Documentation and Downloads:

Product Description

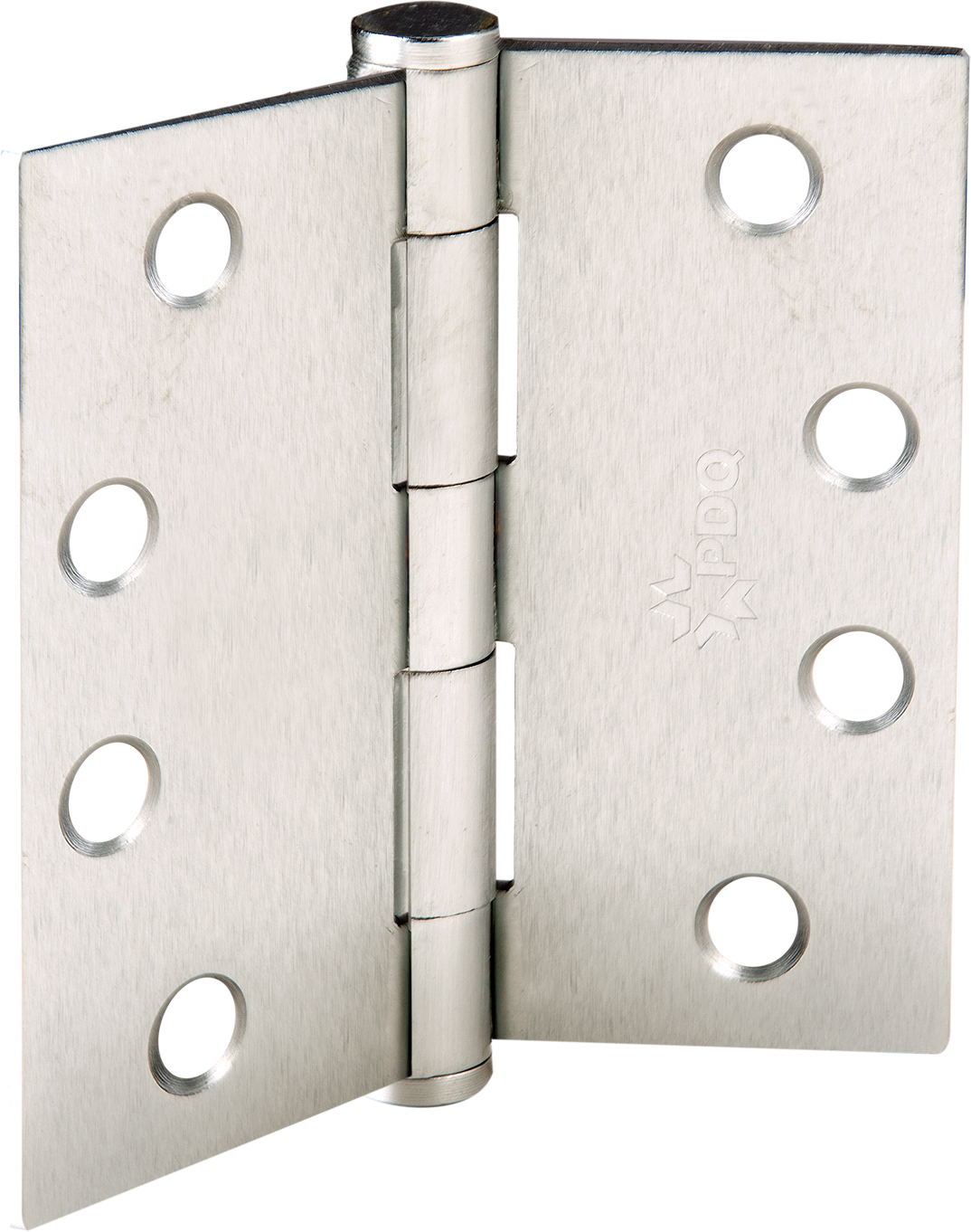

5 Knuckle Plain Bearing Steel Hinge. Certified to ANSI 8133.

Features & Benefits

- Steel Construction .130" thickness

- Grade 3, tested to 350,000 cycles

- 4-Finishes: 600(P), 613(US10B), 619(US15), 652(US26D) (Product Specific)

- Non-Removable pin accepts set screw (3/32" hex) in grooved center barrel

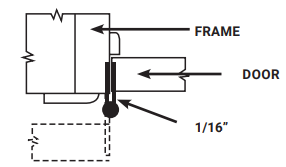

- 1/16" clearance in the closed position

Certifications

- Conforms with the requirements of NFPA 80-2010, Section 6.4.3.1

- Certified to ANSI/BHMA A156.1 Grade 3 A8133

Warranty

- Five (5) year limited